Micro Swiss was founded in 2014 to manufacture 3D printer parts for existing 3D printers. This started with making 3D printer brass nozzles, but soon expanded to complete hotends and aftermarket parts for the most diverse 3D printers, from Creality to Prusa Research.

Skip to product grid

All products in collection: Micro Swiss

-

Vendor:Micro Swiss

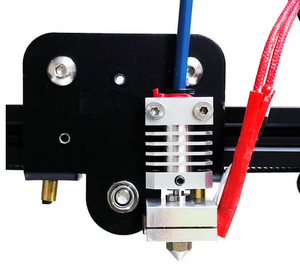

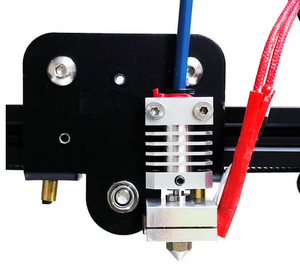

Vendor:Micro SwissMicro Swiss All Metal Hotend Kit for CR-10 / Ender 3D Printers

Regular price €49,99Regular price -

Vendor:Micro Swiss

Vendor:Micro SwissMicro Swiss A2 hardened steel nozzle - M6 - 1.75 mm

Regular price €19,50Regular price -

Vendor:Micro Swiss

Vendor:Micro SwissMicro Swiss Brass coated nozzle - MK8 - 1.75 mm

Regular price €17,50Regular price -

Vendor:Micro Swiss

Vendor:Micro SwissMicro Swiss Brass coated nozzle - M6 - 1.75 mm

Regular price €17,50Regular price -

Vendor:Micro Swiss

Vendor:Micro SwissMicro Swiss coated heatbreak for MK8 hotends

Regular price €13,50Regular price -

Vendor:Micro Swiss

Vendor:Micro SwissMicro Swiss coated heatbreak for E3D V6 hotends - 1.75 mm

Regular price €18,50Regular price