What is a 3D printer nozzle?

Despite the many parts on a 3D printer, the nozzle is often something that is overlooked. It largely determines the quality of the 3D prints and the time of the print job. Choosing the size and material wisely can save you a lot of time in the long run. The nozzle on a 3D printer is the mechanical part from which the 3D printer filament comes from. It conducts the heat from the heater cartridge and heater block to the 3D printer filament to melt it. Based on this you can point out a number of things that are interesting for a design of a 3D printing nozzle; the size, material and inner diameter of the 3D printer nozzle.

Types of 3D printer nozzles

In recent years, many different types of 3D printer nozzles have appeared on the market. These occur with different materials, different coatings or a combination of the two. Let's take a look at them one by one:

1. Brass/brass 3D printer nozzle

Brass (or also called brass in English) is without a doubt the most common material for 3D printer nozzles. It offers excellent heat conduction for a relatively low price. Despite the low price, it also has a disadvantage: it wears out quickly and cannot withstand corrosive materials in 3D printers, such as filaments containing carbon or other filaments containing metals. Brass is a winner up to a temperature of 300 degrees Celsius and without additives.

2. Stainless steel/stainless steel 3D printer nozzle

Stainless steel nozzles have also certainly become popular in recent years. They can withstand corrosive 3D printer filaments a little better and the melted plastic is less likely to stick to them. Another advantage is that stainless steel 3D printer nozzles do not contain lead, making it possible to do food-safe 3D printing. If you plan to use 3D printing to print filaments that contain metal parts or other corrosive substances, stainless steel is still not recommended, but it will undoubtedly last longer. Stainless steel 3D printer nozzles can be used up to 500 degrees Celsius.

3. Hardened steel 3D printer nozzle

The most expensive variant among the 3D printer nozzles is the hardened steel variant. This can 3D print for years without any maintenance and in many cases I can continue to 3D print neatly for the entire lifespan. The use of the tropical 3D printer filaments is also no problem. There are also some disadvantages to using hardened steel 3D printer nozzles. The first is that they are more expensive, about 3x as expensive as a brass variant. Furthermore, they are often more difficult to make of very high quality, so your 3D printing surface can show this. Finally, the temperature of your 3D printer often needs to be set higher, because hardened steel conducts heat less well than the brass variant. We at Filamentz recommend setting this approximately 5 degrees Celsius higher.

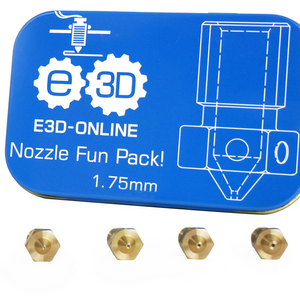

Diameter of 3D printer nozzle

Which diameter 3D printer nozzle should you choose for which print job? That is a question we are often asked at Filamentz. There are a few things to say about this. First of all, it is important to know that 3D printer nozzles are often made from approximately 0.1 mm to 1.0 mm in size. Ultimately, it all has to do with how much filament is melted and how quickly it has to be melted. The most commonly used 3D printer nozzle is 0.4 mm in the industry. This allows good speed to be achieved while still achieving an acceptable level of detail.

3D printer nozzle larger than 0.4 mm

- Faster printing times are achievable

- Fewer problems in general due to the thicker print layers and the absence of details

- Recommended for special filaments such as woodfill filament, due to the pieces of material contained in it

3D printer nozzle smaller than 0.4 mm

- Higher precision can be achieved with more details

- Overhanging parts on your 3D print will be easier to print

- If supporting structures are printed, these will be easier to remove with smaller diameter 3D printer nozzles

Vendor:Micro Swiss

Vendor:Micro Swiss Vendor:Micro Swiss

Vendor:Micro Swiss

Vendor:Micro Swiss

Vendor:Micro Swiss