3D printer nozzle clogged? This is how you solve it!

It happens to everyone with a 3D printer. A 3D printer nozzle that is clogged or no longer runs properly. This can occur with residual material, but also with a filament change that did not go well or incorrectly set temperatures. You can solve this with this set from Filamentz! Everything you need to clean, unclog and properly maintain all 3D printer hotends for years of enjoyment.

How can a clogged 3D printer nozzle be prevented?

Unfortunately, it is unavoidable, but with the right maintenance you can prevent a 3D printer nozzle from becoming clogged. By keeping it clean, choosing the right temperatures and, above all, not 3D printing too many different materials together, your chance of getting a clogged nozzle is very small. Try to do inspections on your print results. Do you see a difference between the 3D prints or even during printing? Then check your nozzle to ensure that the material still flows easily.

What materials do I need to solve a clogged 3D printer nozzle?

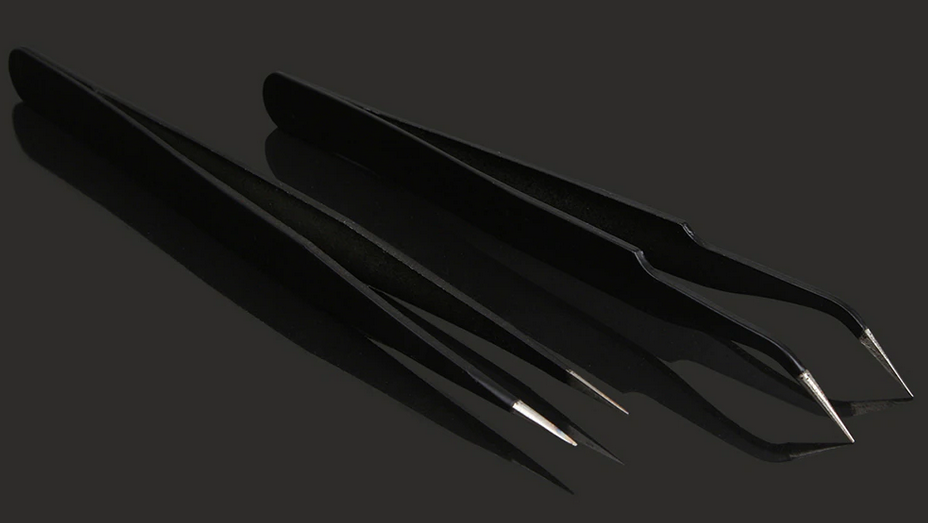

With this set from Filamentz you are largely covered to prevent and solve a clogged 3D printer nozzle. The brush and needles can be used to remove blockages and with the pliers you can prevent filament from sticking to your hotend and staying on it for a longer period of time. This also has the advantage that there is less chance of disrupting your new 3D print with leftover material that is placed on the print bed.

How can you clean a 3D printer nozzle?

The best way to clean your 3D printer nozzle is using the following step-by-step plan:

- Heat the 3D printer nozzle to printing temperature

- PLA about 210 degrees Celsius

- PETG about 240 degrees Celsius

- ABS about 260 degrees Celsius

- In case of a blockage: try to insert the needle of the correct diameter and gently pull it back and forth so that everything in the nozzle is loosened. You often notice that material immediately starts to flow due to the built-up pressure in the nozzle

- Run the brush over the nozzle and the adjacent areas so that everything is optically clean again

- Increase the temperature another 5 to 10 degrees and load new filament and make sure it flows easily. If not, repeat the above steps