Printing with nylon filament can be difficult, as there are quite a few variables to control before and during 3D printing. Despite its difficulties, nylon filament is one of the strongest filaments available and can be used perfectly for functional parts and moving parts. Today Filamentz gives 5 tips for the best printing results!

What can go wrong when printing with nylon filament?

There are quite a number of settings and tips that can be used for printing with nylon filament. There are certainly things that can go wrong when processing nylon filament and mistakes can easily happen. Think about:

- Prints warp from the print bed and come loose during 3D printing

- Layers do not adhere to each other and 3D prints are not as expected strong

- The 3D printer clogs and freezes

- Size tolerances are not as desired

- Details are not 3D printed as desired

Now let's look at the ways to solve these challenges:

1. Dry the nylon filament

There are a few things to check when starting out with nylon filament. First is the type of nylon filament purchased, when it was purchased and how it was delivered. Nylon is known as a hygroscopic material, which means that it absorbs water from the environment and incorporates it into the material. This cannot be prevented with nylon and will always happen! There are a number of ways to tell if moisture has entered the nylon filament. First of all, by loading it into the 3D printer and 3D printing a test piece. Are the walls rough and uneven? Then there is a good chance that there is moisture in it. Do you hear a crackling sound during 3D printing of nylon filament? Then it is certain that it is moisture that escapes during the printing process. However, there are ways to solve this. The four most commonly used solutions for drying nylon filament are:

- Use an oven. Place the nylon coil in the oven for 4 to 6 hours at 70-80 degrees Celsius, remove it and seal in moisture using silica gel and a closed container.

- Use silica gel sachets . Place a layer of silica gel in a container, place the spool of nylon filament in it and leave it for several days to weeks. Please note: this will not remove all the moisture from the material and is not the best solution for successful printing with nylon filament. When printing, it is essential that the nylon filament remains in the container to ensure that no moisture enters it.

- Use a filament dryer . Nowadays there are a number of manufacturers that make dryers for filaments. The time and temperature can be set here and the filament will be brought to the desired degree of dryness. It is also possible to print from this filament dryer, so that no moisture can reach the filament.

- Use a food dehydrator . Not the most obvious option, but it works. These food dryers often go up to about 70 degrees and can be set per time unit, perfect for drying filament. Please note: nylon is quite stubborn to dry and not all food dehydrators are capable of doing this.

2. Set the slicer correctly for nylon filament

Perhaps the most important thing to print successfully with nylon filament is to correctly set the slicer used in which the printing program is created. There are a number of settings that are essential to achieve good results:

- Print temperature: between 240 – 270 degrees Celsius

- Print surface temperature: 70 - 90 degrees Celsius, depending on the type of surface and adhesive material

- Print speed: between 30 – 60 mm per second is recommended for most 3D printers

- Cooling fan: 0% for optimal strength and layer bonding, increase this for details to a maximum of 20%, but never higher than this value

- Minimum print speed: 10 mm/s with a layer time under 60 seconds

- Optimal layer height: 0.2 – 0.3 mm per layer, depending on nozzle size

These settings have been tested and work well with dried nylon to achieve excellent print results. Please note that these settings apply to a standard 0.4 mm nozzle and therefore require more material and therefore more heat for larger openings. Try not to let the volume become too large when printing nylon filament.

3. Check the temperature around the 3D printer

It is something that often occurs with 3D printer filaments that deviate from the standard, namely PLA filament . If the ambient temperature is too cold, the corners of the 3D print will become loose from the printing surface, causing 3D prints to fail or deviate in sizes and tolerances. Nylon filament, like ABS and PETG filament , is also extremely sensitive to this. To prevent this, it is necessary to create an environment around the 3D printer that is constant in temperature and around 35 - 40 degrees Celsius. This means that 3D prints stick better to the surface, the layers adhere better to each other and they are also stronger. Please note that the 3D printer is of course also suitable for this, in terms of electronics and other controls. The way to close the 3D printer can be by means of a nylon cover, which is offered in various places, or by means of wood, plexiglass, an optional external heater and a power supply . Please note that this can of course cause a fire hazard and that you do so at your own risk.

4. Use the correct printing surface with the appropriate adhesive materials

As mentioned, nylon filament is difficult to adhere to the 3D printing surface. However, there are ways to solve this. First of all, the conditions under which printing takes place. The ambient temperature is good and the settings in the slicer are set correctly according to the supplier's specifications. Then there is the correct selection of the printing surface. Nylon filament generally adheres well to PEI surfaces, using a prit marker to ensure it does not coalesce. It is also advisable, if you often print with nylon filament, to purchase a garolite printing surface. This material adheres perfectly to nylon filament and ensures that it comes off easily when it cools. Please note that these surfaces are difficult to obtain and can therefore be quite expensive. Glass is not recommended as a surface, because nylon can virtually fuse with it. To get this working, a prit marker is also required.

5. Orient the 3D print optimally for nylon filament

Finally, orienting the 3D print is important for getting a good printing result. Don't forget the reminders below when preparing the 3D print:

- Try to avoid support structures when printing with nylon filament, as they are difficult to remove

- Do not attempt to print large flat surfaces without making sure the printer is in an enclosure where the temperature is constant, otherwise the risk of failure is high

- Add a brim to the 3D print of approximately 5 to 10 mm to ensure better adhesion of the 3D print

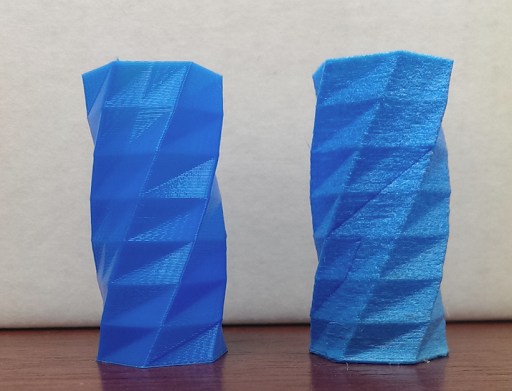

- Try printing a calibration cube or a part with more detail first, to optimize speeds and ensure the nylon filament is moisture-free and delivers good results

Nylon is a wonderful material for 3D printing but needs some attention to be a success. We at Filamentz are always willing to think along with you about possible problems. Also read our other articles to be assured of success with 3D printing.