A 3D printer is a machine that makes it possible to convert a 3D model into a physically tangible product, using an additive technique that supplies material and builds it up layer by layer. The 3D printing technique has increased enormously in popularity in recent years, making it increasingly affordable and easy to apply in daily life. Scientists expect the additive industry to grow by an average of 17% annually until 2026.

How a 3D printer works

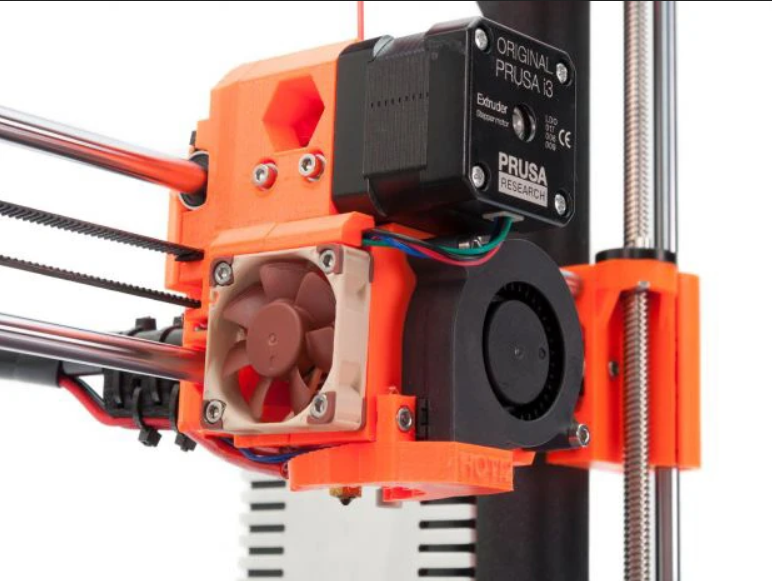

An FDM 3D printer works in layers, in which molten plastic is deposited through a print head with an opening varying between 0.2 and 1.5 mm in diameter . This consumable material is heated between 200 – 300 degrees Celsius and fed through gears. A 3D printer also consists of a movement system, which ensures movements in the X, Y and Z directions. The drives of these moving parts are mainly stepper motors, but can be transmitted by belts, linear guides and bearings. Furthermore, a 3D printer also has a control section that converts generated codes into printing movements and also monitors the temperature controls. The generated codes mentioned are created in a so-called slicer, which converts the created 3D model into code language for the 3D printer, also called Gcode.

Operation of an SLA 3D printer

An SLA 3D printer works with a liquid synthetic resin bath, also called resin, and with UV lasers, which harden in layers varying between 0.025 and 0.2 mm. SLA 3D printers are known for their extremely high quality 3D prints and the details that can be created with them. SLA 3D printers generally work with two axes. The liquid resin bath that moves back and forth and a platform that goes up and down in the Z direction, to continuously harden a layer of synthetic resin. Because resin 3D printers generally print 3D in reverse, models are often printed upside down. To prevent errors and to prevent forces on the (usually fragile) 3D prints, many suppliers install tilting mechanisms on the 3D printer. To 3D print a new layer, the following movements will take place in chronological order:

- Platform sinks into the liquid resin

- UV lasers harden a resin layer between 0.025 and 0.2 mm thick

- Platform rises from the liquid resin when the layer has hardened

- A slide sweeps a fresh layer of liquid resin under the platform

- The platform sinks back into the liquid resin for the next layer

This will be repeated until the 3D print is ready.

Operation of an SLS 3D printer

An SLS 3D printer is based on a container full of nylon powder, which is hardened by means of lasers at a high temperature, varying between 0.1 and 0.3 mm thick . SLS 3D printing does not require any support material, as the powder is the basis for it. All powder that has not hardened during 3D printing can largely be reused in the next print job. SLS 3D printing works in a powder bed, where it is built up layer by layer by high-temperature lasers. Each layer, a fresh layer of powder is placed on the print, allowing objects to be created with great freedom of form. SLS mainly works with nylon (PA11 and PA12) powder, which is characterized by its strength, flexibility and impact resistance.

Parts of a 3D printer

A 3D printer largely consists of the following parts:

- A (heated) print bed

- A print head consisting of print mouth, heating element and temperature measurement

- A supply system of printing material, also called filament

- Movement system in the X, Y and Z directions including stepper motors

- A control board that regulates movements and temperatures

- A probe, to measure the distance between print head and print bed

- End position indicators, to indicate the maximum print volume

- A filament sensor, to indicate when the material has run out

- A power supply that powers the print head, control board and print bed

These parts will not change much between the different suppliers of 3D printers, but they can differ greatly in quality. The method of 3D printing can also be different, which also changes the above.

Various 3D printers

There are many different 3D printers in the current market. The largest part consists of:

-

FDM 3D printers, consisting of cartesian, coreXY and delta 3D printers

- Works using heated plastic and is controlled by Gcode

-

SLA 3D printers

- Works using liquid synthetic resin that is hardened using UV lasers

-

SLS 3D printers

- Works using powder, which is hardened by lasers and can be printed without support

-

DLP 3D printers

- Works almost the same as SLA 3D printers but does not use UV light but a light projector

-

Binder jetting

- Works by means of a binding agent that can be used between different raw materials, often sand or ceramics.